EVA valve bag is packaged in double-layer pleated valve port EVA melting bag, which has good miscibility with the paint. When in use, it is put into the hot melt kettle together with the paint to be melted.

Item No.:

EVA valve bagsBrand:

iSuoChemColor:

Clear or whiteAppearance:

BagDouble Layer Hot Melt EVA Valve Bag For Road Marking Paint

Parameters of Hot melt EVA valve bags:

| Other names | Hot applied thermoplastic mass |

| Characteristics | Double layer EVA valve bags |

| Material | EVA+PE |

| Length | 610±10mm |

| Width | 350±10mm |

| Melting point | 100±5℃ |

| Single layer thickness | 6.0s±0.5s |

| Weight | 63±5g |

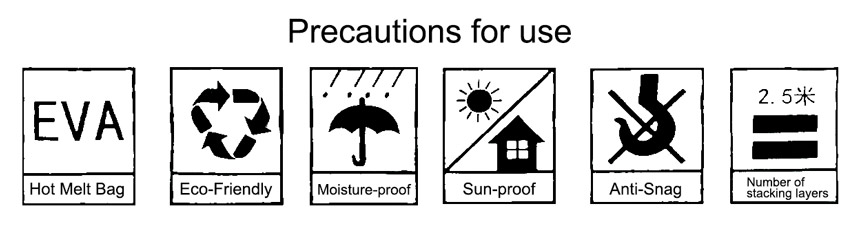

Packaging

Instructions for hot melt EVA valve bag to be used in road marking paint

1. The road surface must be clean, dry and dust-free. Remove old markings and other adhesives that are poorly adhered.

2. The construction temperature of hot-melt reflective paint is 200℃±10℃.

3. The surface glass beads should be spread evenly, and the sedimentation depth should be about 60% of the diameter of the glass beads. The recommended surface spreading amount is not less than 500g/m².

4. Hot melting EVA Valve bag is packaged in a double-layer frilled valve EVA melting bag, which has good miscibility with the paint. When used, it is melted in the hot melt kettle together with the paint.

5. The weight of this EVA valve bag package is suitable for 25kg±0.5kg. During handling and transportation, please place it horizontally to prevent scratches from sharp objects.

6. There are tiny exhaust holes around this EVA valve bag package, please pay attention to rain and moisture protection.

7. This EVA hot melting valve bags are designed with a separate formula.

8. Do not melt petroleum resin paint and rosin resin paint at the same time to avoid the formation of surface spots on the marking line after marking.

9. When applying to old asphalt and cement pavement, please apply a primer that matches the paint. The pavement that has been coated with the primer must complete the marking construction within the same working day. If the pavement that has been coated with the primer is not marked within the specified time, the primer must be re-sprayed.

10. When applying to new cement pavement, please remove the alkali layer on the cement surface before applying the primer and marking.

Notes for thermoplastic road marking paint packed by EVA valve bags:

1. The hot melt reflective paint should not be kept warm at above 210℃ in the hot melt kettle for more than 6 hours.

2. The number of times the melted paint is re-melted should not exceed 3 times.

3. If there are burnt particles on the filter screen during discharge, please adjust the flame intensity and clean it.

4. When switching from petroleum resin paint to rosin resin paint, please clean it up, and vice versa.

5. Do not use hot melt paint that has been damp or rained on to avoid splashing and scalding during melting.