PE-802 is a high-performance polyolefin nucleating agent specially for Polypropylene materials.

Item No.:

PE-802Brand:

iSuoChem®Color:

WhiteAppearance:

PowderPolyolefin nucleating agent PE-802 is a high-performance nucleating agent specifically formulated for polypropylene. This advanced additive significantly refines the crystal structure and ensures a uniform crystal size distribution within the polymer. The result is an exceptional balance of stiffness and toughness in the final product.

As an efficient nucleating agent for polypropylene, PE-802 raises the crystallization temperature, which shortens the molding cycle. This leads to faster production speeds and improved overall product performance, making it a cost-effective solution for manufacturers.

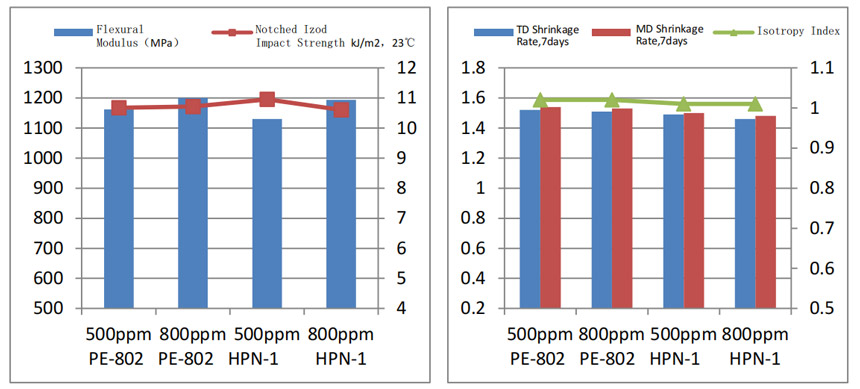

High-Efficiency Nucleation: Achieves a high crystallization temperature for ultra-fast molding.

Superior Stiffness/Toughness Balance: Enhances both rigidity and impact resistance.

Low & Uniform Shrinkage: Minimizes shrinkage and ensures consistency in both flow and transverse directions, reducing part warpage.

Food Safety Compliance: Suitable for food contact applications.

ICP Powder (MI=28) + Antioxidant System + Nucleating Agent

PE-802 is versatile and can be used in polypropylene extrusion, injection molding, and compression molding processes.

Typical applications include:

Household Appliances(Washing machines and small appliances)

Automotive Modified Materials

Electronics and Electrical Appliances

Plastic Bottle Caps

Various Household Plastic Products

Q: What is the recommended dosage of nucleating agent?

A: For optimal performance, it is recommended to add 0.04% to 0.3% of PE-802. The specific dosage can be adjusted based on your actual requirements.

Q: How to mix and disperse the nucleating agent?

A: To use this nucleating agent, mix it with polypropylene powder or pellets using high-speed mixing until uniform. Then transfer the mixture to the extruder feeder for granulation. Adding a small amount of white mineral oil during mixing can improve adhesion and dispersion, preventing segregation.

Q: How about masterbatch option?

PE-802 is also available as a high-concentration masterbatch, which can be diluted to your desired dosage for easier handling.

Q: How about Extrusion Granulation?

We recommend using a twin-screw extruder or a high-intensity single-screw extruder. Good dispersion is key to maximizing the nucleation agent effect and the physical properties of PE-802. Extrusion temperatures and other parameters can typically follow standard polypropylene processing guidelines without major adjustments.

Q: Do you only offer nucleating agents for polypropylene?

No.

A nucleating agent is an additive whose core function is to provide a "template" or starting point for the plastic[Polyethylene (PE), Polyamides (PA), Polyesters (PET, PBT), and Polylactic Acid (PLA) ] as it cools and solidifies, allowing the plastic molecules to more orderly and quickly arrange into a crystalline structure. Our Polyolefin Nucleating Agent for PP, model number PE-802, is just one of our nucleating agents.