1.1 What is HMPA (Hot melt polyamide resin) ?

Polyamide resin has a history of more than 60 years. The structure of polyamide resin is complicated, but because of its regular structure, symmetry, small steric hindrance and polarities containing amide groups, it has the characteristics of easy crystallization, high melting point and poor solubility, so it is difficult to use as a hot melt adhesive.

With the development of polymer chemistry, people have further understanding and research on the structure of polyamide, and modified polyamide hot-melt adhesive with excellent performance. It’s now widely used in footwear, clothing, electronics, telecommunications, home appliances, automobiles and machinery industries.

Polyamide hot melt adhesives are mainly thermoplastic polyamide resins.

2.1 Why Choose HMPA's (Hot melt polyamide resin) ?

Easy Processing (e.g. low pressure molding)

Chemical Resistance

Heat Resistance Strength

Low Temperature Resistance

PVC Plasticizer Resistance

Green Strength

Long Open Time

Adhesion to porous substrates

Ink Grade vs HMPA Grade

Typically, ink grade is lowest cost

Cheaper raw materials

Processing on belt vs. underwater pelletizer

Flexibility

Adhesion to polar and non-polar substrates

High temperature resistance

2.3 Our Honor

R&B Softening point, Sometimes R&B range

Example 130C, 125 to 135C

Brookfield viscosity @ specified temperature, typically cps

Example 18,000 cps at 190C

190C is typical

Higher softening points will use 205C and higher, up to 230C

HMPA’s start to degrade at 240-250C

Termination

Acid

Some believe better thermal stability

Amine

Some believe better adhesion

Color (Gardner value in solution – typically 20% to 40%).

Typical value is 8

Mechanical Properties

Adhesion strength

Electrical Properties

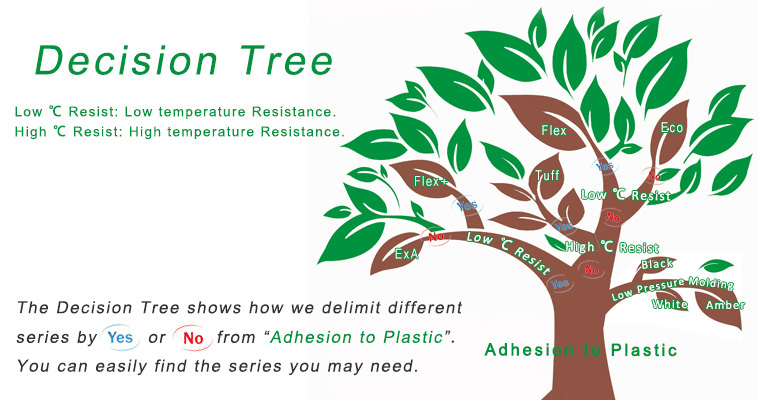

3. Product Series

These categories provide targeted solutions for all major bonding problems and substrates covering a wide range of industries including automotive, tape, footwear, electronic, medical, packaging, wood assembly, carpet and textiles.

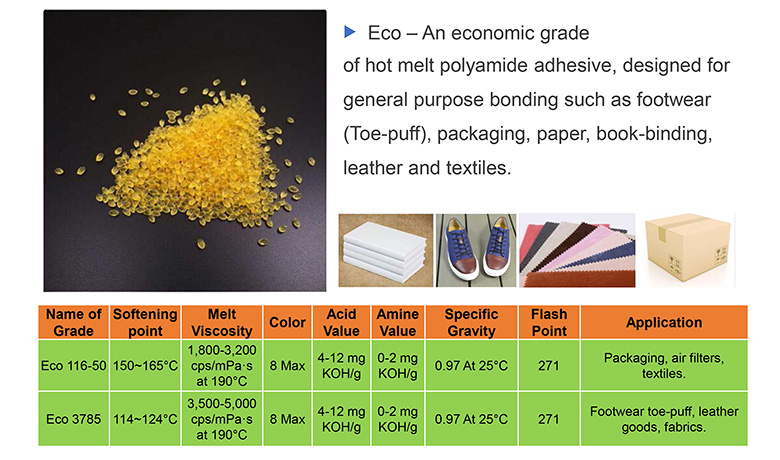

3.1 Eco Series

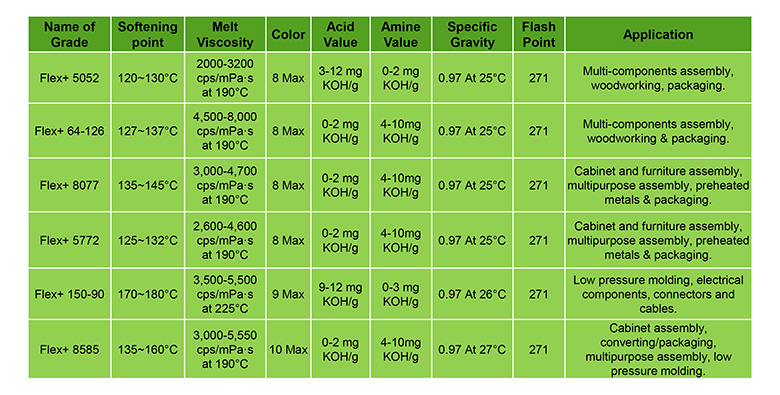

3.3 Flex+ Series

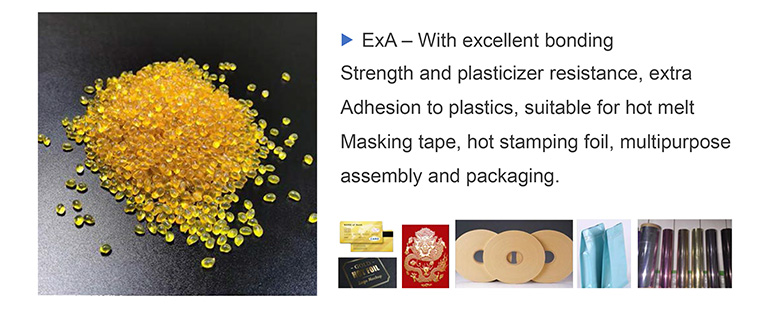

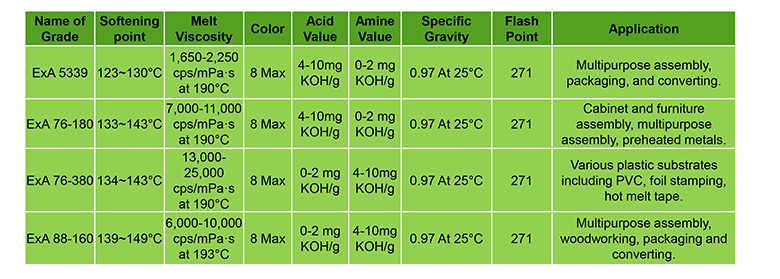

3.4 ExA Series

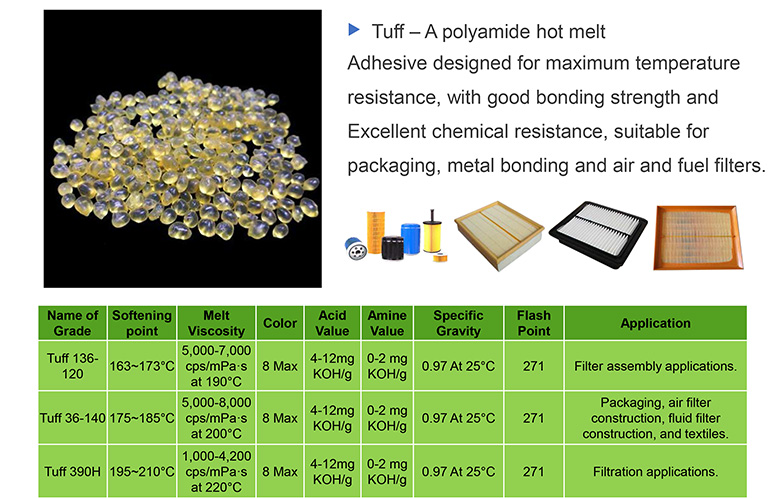

3.5 Tuff Series

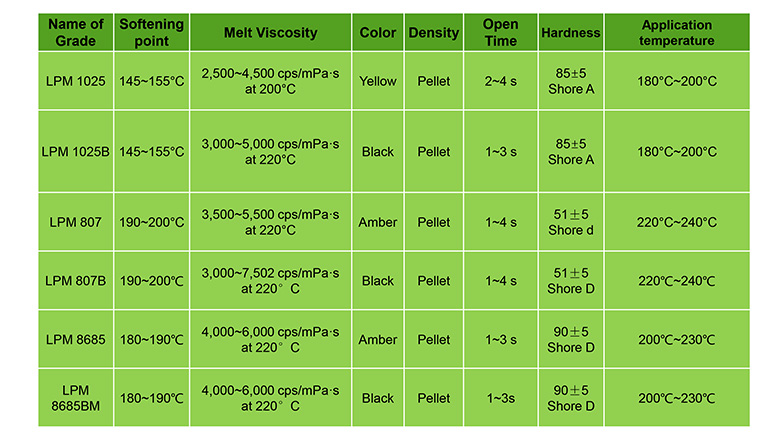

3.6 LPM Series

3.7 Decision Tree