Dr. Robert | Senior Ink Technology Specialist | 18 Years Industry Experience

Key Takeaways: Gravure and flexographic inks are two major ink types in the printing industry, each with unique characteristics and applications. Gravure inks are known for their high saturation and fine printing effects, while flexographic inks are favored for their environmental friendliness and wide adaptability. Proper ink selection is crucial for print quality and cost control.

Gravure ink, also known as intaglio ink, is a type of ink specifically designed for gravure printing. It works by filling the recessed image areas of the printing plate with ink, scraping off the ink from non-image areas, and finally transferring the image to the substrate through pressure.

Gravure inks can be classified based on plate-making methods, ink characteristics, and printing press types:

· By Plate-making Method: Photogravure inks, Engraved gravure inks

· By Ink Characteristics: Water-based gravure inks, Alcohol-based gravure inks, Benzene-based gravure inks, Plastic film inks

· By Printing Press Type: Flatbed gravure inks, Rotary gravure inks

Gravure Inks machine (Pearl ink by Gold pearl pigment)

Gravure ink formulations typically contain the following components: Resin (35%-40%), Pigments (8%-16%), Fillers (2%-5%), Solvents (30%-35%), and Additives (10%-20%).

Common solvents include alcohol solvents (ethanol, isopropanol), ester solvents (ethyl acetate, butyl acetate), benzene solvents (toluene, xylene), and ketone solvents (cyclohexanone, butanone).

Flexographic inks were originally called "aniline inks" and were later renamed "flexographic printing inks." Their characteristics include low viscosity, fast drying, and excellent environmental properties.

Flexographic inks are classified by solvent type:

· Solvent-based Flexographic Inks: Suitable for non-absorbent materials like plastic films and metal foils

· Water-based Flexographic Inks: Suitable for absorbent materials like paper and cardboard, environmentally friendly and safe

Flexographic ink formulations typically include resins, pigments, solvents, and additives. Drying mechanisms include evaporation drying, penetration drying, and reactive curing.

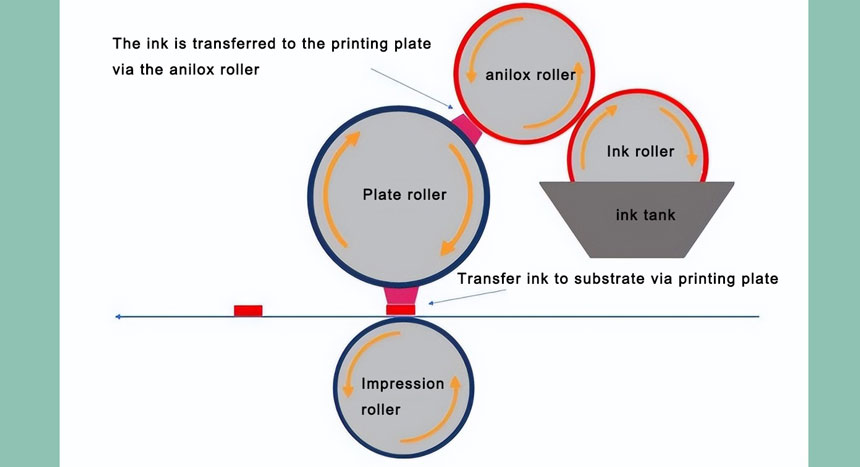

Flexographic ink printing method

|

Comparison Aspect |

Gravure Inks |

Flexographic Inks |

|

Printing Principle |

Image transfer via ink stored in plate recesses |

Ink transfer via flexible plate and anilox roller |

|

Ink Viscosity |

Higher viscosity, suitable for fine printing |

Lower viscosity, suitable for high-speed printing |

|

Suitable Substrates |

Paper, plastic films, metal foils |

Paper, cardboard, plastic films |

|

Printing Precision |

High precision, suitable for fine patterns |

Medium precision, suitable for large solid areas |

|

Drying Method |

Primarily solvent evaporation |

Combination of evaporation, penetration, and reactive curing |

|

Environmental Impact |

Traditional types have environmental concerns; new water-based and benzene-free inks are improving |

Water-based inks have excellent environmental properties |

|

Printing Speed |

High-speed printing, up to 150 m/min |

High-speed printing with good adaptability |

|

Cost Factors |

Higher plate costs, suitable for long print runs |

Lower plate costs, suitable for short to medium print runs |

Expert Recommendation: When selecting ink type, consider the printing substrate, printing speed, precision requirements, environmental standards, and budget constraints. For high-precision, long-run printing needs, gravure inks are preferable; for applications requiring high environmental standards and adaptability, flexographic inks have the advantage.

· Pearlescent Pigment Series (Silver white pearl pigment, gold luster pearl pigment, colored pearl pigment, and other series)

· Glitter & Sparkle Materials

· Organic Pigments

· Fluorescent Pigments

· Reflective Powders

· Aluminum Pigments

· Chameleon Pigments

· UV Stabilizers & UV Absorbers

· CPP Resins

· Polyamide Resins

· CEVA Resins

· PVB Resins

· Other Ink Binders

· Adhesive Series

· High-precision printing (cigarette packaging, pictorials)

· Flexible packaging and composite packaging

· Applications requiring special visual effects (pearlescent, metallic)

· Long print runs with high volume

· Large solid areas and text printing (labels, cartons)

· Food packaging and publication printing

· Applications with high environmental requirements

· Short to medium print runs requiring flexibility

With growing environmental awareness and technological advancements, both gravure and flexographic inks are evolving toward more eco-friendly and higher-performance solutions:

· Environmental Sustainability: Water-based and benzene-free inks are becoming mainstream, reducing VOC emissions

· High Performance: Developing ink formulations for higher printing speeds and better print quality

· Functional Inks: Growing demand for inks with special functions (anti-counterfeiting, antibacterial)

· Standardization: Increased proportion of universal inks to reduce printer inventory pressure

2025 Printing Materials Technology Institute | This article is for reference only; consult professional technicians for specific applications