>>What is Heat transfer Vinyl?

Heat transfer Vinyl is a kind of medium material in thermal transfer process. Thermal transfer process is a one-time heating to transfer the decorative pattern on the thermal transfer lettering film to the surface of the substrate to be decorated to form a high-quality The process of finishing the mask. In the thermal transfer process, the protective layer and the pattern layer are separated from the polyester substrate by the combined action of heat and pressure, and the hot melt adhesive makes the entire decorative layer and the substrate permanently glued. It has the characteristics of high temperature resistance, no deformation, no degumming, convenient operation and easy waste discharge.

>>What are the classifications of Heat transfer Vinyl?

1.PVC Heat transfer Vinyl

The main material is PVC+TPU, the effective thickness is 120-140um, the hot stamping temperature is 150-160℃, the hot stamping time is 10-15s, and the size is 50cm*25m/roll.

The material of PVC lettering film is hard and inflexible, and the weather resistance is relatively poor. The advantage is that it is cheap

Scope of application: textile fabrics such as clothing and luggage.

2.PU Heat transfer Vinyl

The main material is PU, the effective thickness is 110-130um, the hot stamping temperature is 150-160℃, the hot stamping time is 10-15s, and the size is 50cm*25m/roll.

PU lettering film is suitable for sportswear, it is elastic and weather resistant, and the price is twice that of PVC lettering film

Scope of application: cotton, polyester, acrylic fiber and similar fiber clothing, bags, hats.

3.TPU Heat transfer Vinyl

The main material is TPU, the effective thickness is 110-130um, the hot stamping temperature is 160-170℃, the hot stamping time is 10-15s, and the size is 50cm*25m/roll.

TPU lettering film has similar characteristics to PU. It is suitable for sportswear. It is elastic and has strong weather resistance. However, TPU has more toughness than PU and can better avoid cracking. The price is slightly higher than PU, but the difference is not much.

Scope of application: cotton, polyester, acrylic fiber and similar clothing, luggage, hats.

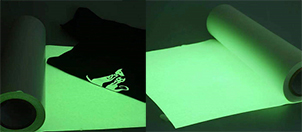

4. Glow in dark Heat transfer Vinyl

The effective thickness is 150-200um, the hot stamping temperature is 150-160℃, the hot stamping time is 10-15s, and the size is 50cm*25m/roll.

Scope of application: high temperature resistant textile fabrics such as clothing, luggage, shoe materials, special DIY textiles.

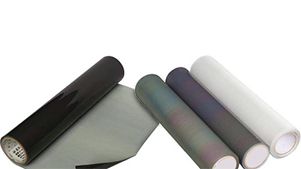

5. Reflective Heat transfer Vinyl

The effective thickness is 150-200um, the hot stamping temperature is 150-160℃, the hot stamping time is 10-15s, and the size is 50cm*25m/roll.

Scope of application: high temperature resistant textile fabrics such as clothing, luggage, shoe materials, special DIY textiles

6.Glitter Vinyl

The effective thickness is 170-200um, the hot stamping temperature is 150-160℃, the hot stamping time is 10-15s, and the size is 50cm*25m/roll.

Scope of application: cotton, polyester, acrylic fiber and similar fiber clothing, bags, hats.

7.Metallic Vinyl

The effective thickness is 120um, the hot stamping temperature is 150-160℃, the hot stamping time is 10-15s, and the size is 50cm*25m/roll.

Scope of application: textile fabrics such as clothing and luggage.

8.Matte Vinyl

The effective thickness is 120um, the hot stamping temperature is 140-160℃, the hot stamping time is 8-12s, and the size is 50cm*25m/roll.

Scope of application: non-waterproof fabrics such as clothing, canvas bags, pennants, leather, etc.

9.Holographic Vinyl

The effective thickness is 120um, the hot stamping temperature is 155-165℃, the hot stamping time is 8-12s, and the size is 50cm*25m/roll.

Scope of application: clothing, bags, hats, shoes.

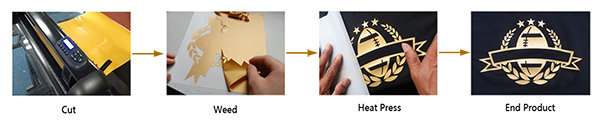

>>Process flow

The thermal transfer engraving film is cut with a computer engraving machine and laser, first cut into the required shape-tear off the non-patterned film-the thermal transfer engraving film is hot, the temperature is generally 140-180 ℃, the time is 10-15S, According to different materials and requirements-after the product is cooled, tear off the surface PET film-finished product.

>>Matters needing attention for thermal transfer printing film:

In the process of hot stamping, the lettering film should pay attention to the three principles of hot stamping: temperature, time and pressure.

During storage, avoid high-temperature storage and keep it away from fire or heat sources. The processed semi-finished products are not allowed to be stacked on each other, especially the adhesive surfaces are attached to each other, which will easily lead to anti-sticking, resulting in waste and loss. Strong light environment

Pay attention to the transfer process, heat transfer film should be handled gently, not horizontally, but it must be placed vertically or upright.