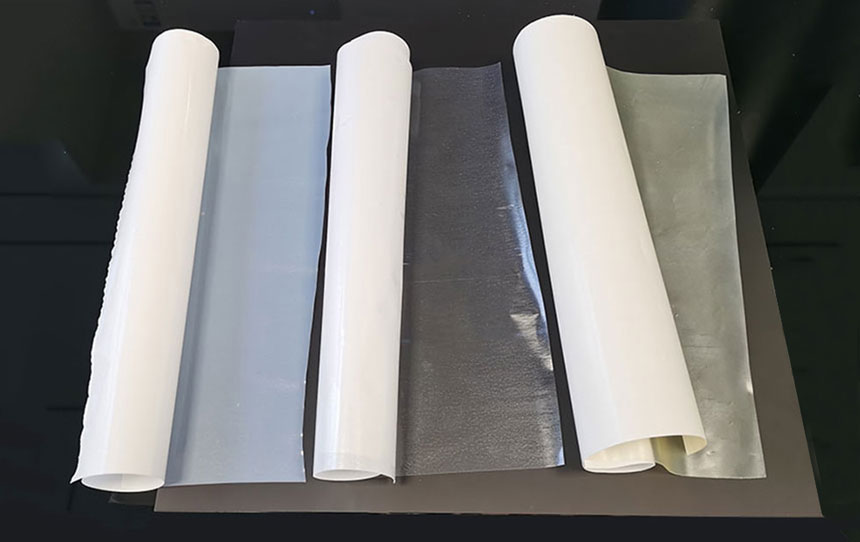

Hot Melt Adhesive Film is the adhesive formed in film with or without Release Paper.

Item No.:

9341FBrand:

iSuoChemColor:

ClearAppearance:

Film form

Spiderbond 9341F web adhesive is a film form hot melt adhesive produced based on TPU. Film adhesives handle like a fabric facilitating both intermittent and continuous processes. The TPU film is available in a range of thickness from 15 to 250 micron.

Adhesive Film Feature:

Self fusible, Double sides fusible.

VOC free adhesive in easy handle film form.

Strong bonding strength and good anti-washing performance.

Specifications

|

Property |

Detail or Method |

Specification |

|

Appearance |

By eye |

Milky white film |

|

Base |

|

TPU |

|

Thickness |

micron |

15-250, tolerance ±10% |

|

Melting range |

DSC, °C, GB/T 19466.3 |

Around 40-60 |

|

Density |

g/cm³, GB/T13354-1992 |

1.2-1.3 |

|

Water Wash Temperature |

°C |

40 |

9341F can be activated with any of the following techniques: electric fusing press, heated rolls, heated air, radiant heat, or steam press. Dry heat activation recommend above 80°C.

Bonding Surface Preparation: Bonded surfaces need to be clean, dry and free of grease.

Preparation: Set the appropriate temperature for the glue applicator/roller, too high temperature will cause the film to decompose. According to the structure of the equipment, it is generally enough to adjust the process reasonably to reach 130 °C. In general, preheating the material to be bonded is more conducive to material bonding, especially in cold weather.

Flat pressing

Temperature: 100-140℃

Pressure: 0.2-0.6Mpa

Time: 5-12s

Complex machine

Temperature: 110-160℃

Roller speed: 3-15m/min

Main Applications of Hot melt adhesive film:

9341F film adhesive is based upon high performance TPU. This product has harder hand feel, low working temperature, fast crystallization speed and high peel strength, suitable for bonding PVC, artificial leather, fabric, fiber and other materials that need to be used at a lower temperature.

This product is the most popular product in insole lamination.

9341F should be shipped and stored at temperatures 10-35°C. The shelf life of 9341F is one year since production date under these conditions.